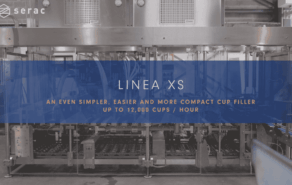

The ideal filling solution for small production runs

Serac Bottle and Cup Filling Machines for Yogurts and Dairy-Free Yogurts

Serac designs and manufactures yogurt filling machines and dairy packaging equipment for yogurt products in cups and jars, as well as cultured drinks in bottles in the USA. Our solutions deliver end-to-end, hygienic, and precise industrial yogurt packaging — spanning from net-weight rotary yogurt filling and capping technology to advanced volumetric yogurt cup filling and sealing machines.

Serving the USA and Canada since 1981, Serac is the trusted partner for seamless integration, high performance, and sanitary design.

Key Benefits of Serac Yogurt Filling Solutions:

- Hygienic design with 3-A Sanitary Standards (USA) & easy to clean

- Precise filling & minimal waste

- Flexible recipes & particles

- Scalable to any industrial capacity.

- Quick change-over between multiple products

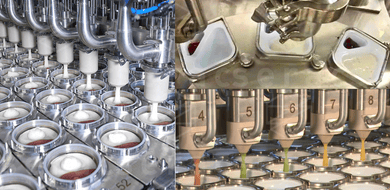

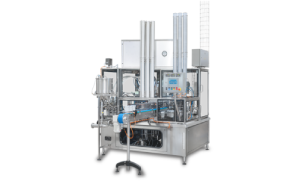

Serac Volumetric Cup Filling Machines for Different Yogurt Types

- Ideal for yogurt products in round and rectangular cups (PS/PP/PET, Carton, Paper)

- 800 to 6,000 cups per hour for rotary filling machines & up to 60,000 cups per hour for linear filling machines

- Able to dose up to 5 different fillings at the same time, suitable for a wide variety of recipes with or without layers, particles and compartments

Serac Net Weight Filling Technology for Yogurts and Cultured Drinks

- Ideal for yogurt products in single-serve bottles, non-stackable cups and jars at high speed (PS/PP/PET, Glass, Paper)

- Low-Medium-High Speed Production: 3,000 to 50,000 bottles per hour

- The most accurate option in the filling market, 1gr sigma per 1000gr

Yogurt Cup Filling and Sealing Solutions

Our automatic yogurt cup filling machines deliver precision volumetric filling technology for industrial yogurt packaging operations. From small-batch artisan production to high-speed manufacturing, our yogurt cup filling and sealing machines provide flexible, hygienic solutions for all cup formats.

Key Advantages of Our Yogurt Cup Filling Equipment

| ✓ Reliability | Mechanical precision for consistent filling performance |

| ✓ Flexibility | Accommodates diverse recipes and container types |

| ✓ Accuracy | Volumetric technology ensures precise dosing |

| ✓ Cleanliness | Automatic CIP cleaning reduces downtime |

| ✓ Versatility | Perfect for dairy and plant-based alternatives |

| Feature | Rotary Yogurt Filling Machines | Linear Yogurt Filling Machines |

|---|---|---|

| Capacity | 800 – 6,000 cups/hour | 4,000 – 60,000 cups/hour |

| Filling Stations | Up to 3 | Up to 5 |

| Best For | Small to medium production | High‑volume industrial production |

Multi-Product Dosing Capabilities

Advanced Features:

- Dose up to 5 different products at the same time

- Multiple nozzle options including Modulo nozzle for liquid and viscous products

Filling Methods:

- Helical filling – Smooth texture preservation

- Layered filling – Multiple products in distinct layers

- Crowned multi-product filling – Premium presentation

- Product-on-product placement – Fruit, granola, or toppings

Compatible Container Types

Materials: PET, PP, PS, Glass, Carton/Paper

Container Formats:

- Stackable cups (PS/PP/PET, Carton/Paper)

- Non-stackable containers (Glass, Ceramic jars)

- Round and rectangular shapes

- Compartmented cups for separated ingredients

Product Versatility & Applications

Our yogurt cup filling and sealing machines handle all yogurt & cultured dairy dessert consistencies and recipes:

- Liquid & Smooth – Traditional yogurt, flavored yogurt

- Creamy – Greek yogurt, Icelandic skyr, custard-style, pudding

- Aerated/Whipped – Mousse-style, whipped yogurts

- Thick/Pasty – High-protein yogurts, cultured dairy desserts with cream cheese, quark

- Set/Firm – Set-style yogurt, panna cotta, premium custards

- With Particles – Fruit chunks, granola, chocolate, seeds

- Mixed in yogurt (e.g., fruit-on-the-bottom, blended parfaits)

- In compartmented cups (e.g., toppings added by consumer)

- Sticky Components – Caramel, honey, fruit syrups for layered or topped yogurts

Sealing & Closure Options

Heat Sealing for Yogurt Cups:

- Aluminum foil (conduction heat sealing, induction heat sealing)

- PET/PP foil (pre-cut or rollstock)

- Paper sealing for sustainable packaging

Overlid Options:

- Snap-on plastic lids

- Screwcaps

- Carton or metal closures

Hygienic Design Standards

Safety Features:

- Built to Hygienic Design Guidelines – 3-A Sanitary Standards (USA)

- Stainless steel AISI 316 product circuit

- Automatic CIP cleaning system

- Splash-free nozzle movement

Decontamination Options for Extended Shelf-Life:

- H₂O₂ packaging treatment

- Pulsed light technology

- UV sterilization

Complete volumetric filling solutions for modern dairy and dairy-alternative production facilities, combining speed, precision, and hygienic operation for cups ranging from single-serve to family-size formats. Our automatic yogurt cup filling machines and dairy packaging equipment deliver proven technology for North American producers.

Got more questions? See our FAQs section or contact us to know more

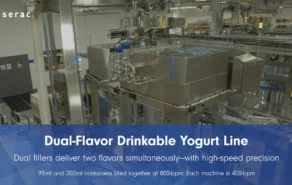

Yogurt Net Weight Filling Solutions

Precision rotary filling machines delivering ±1g accuracy for yogurt, yogurt drinks, kefir, smoothies, and protein shakes. Handles cultured dairy & dairy-free products from 2 fl oz to 1 gallon at 3,000–50,000+ bottles/hour.

Why Choose Net Weight Technology

- Superior Accuracy: ±1g sigma per 1000g bottle

- Versatile Product Handling: Manages liquid to viscous (up to 40,000 cP), foamy textures, and particles up to 10×10×10mm

- Temperature-Independent: Maintains precision despite fermentation heat or aerated products

- Hygienic Design: Meets 3-A Sanitary Standards and USDA requirements with automatic CIP cleaning

Product & Packaging Flexibility

Products: Yogurt drinks, kefir, probiotic yogurts, Greek yogurts, high-protein shakes, dairy-free alternatives

Containers: Bottles, non-stackable cups, jars, and pails (PET, rPET, HDPE, glass, paper); round/rectangular shapes

Closures: Aluminum foil heat-sealing, screw caps, twist-off, snap-on

ESL Options: Peracetic acid, H₂O₂, BluStream, UV, pulsed light, ozonated water treatments

Key Technical Advantages

- Filling valve options adapted to your products

- No-contact splash-free nozzles prevent cross-contamination

- Self-control and self-adjusting net weight system to keep consistency and repeatability of the fill

- CIP with options of CIP modules

- Low maintenance requirements, lower operational costs

Production capacity: Medium to high-speed rotary configurations; 3,000–50,000+ bottles/hour

Filling accuracy: ±1g per 1000g

Container sizes: 2 fl oz to 1 gallon; bottles, non-stackable cups, jars, pails

Discover how Serac’s net weight filling technology can optimize your yogurt packaging line, reduce giveaway, and extend shelf life.

Visit Serac’s dairy filling solutions for complete bottling systems designed for milk and liquid dairy products.

Liquid Dairy & Milk Packaging Machinery Manufacturer in North America

Serac Inc designs, engineers and builds machines in the USA. Our proximity is enhanced by our international presence & expertise, allowing us to offer unmatched services at the highest standards across the Americas.

Welcome to Serac Inc, where we make filling, capping and sealing machines for yogurt products and dairy-free alternatives in cups and bottles

Our factory in Carol Stream, IL is open for Visits.

FAQS

Frequently Asked Questions

-

How much does a yogurt filling machine cost?

Filling Machine Cost Estimation

Budget is key. The cost of a filling machine depends on a lot of factors:

- The packaging format: shapes, materials, sizes

- The product recipes

- The production speed per hour

Contact us with these details to get an estimation

-

What are the downtimes with your yogurt fillers?

CIP, Changeovers and Maintenance

Downtime costs money. Serac machines are designed with the highest hygiene standards and flexibility in mind. Most common downtime of our machines:

- CIP : ± 45 to 90 minutes

- Changeover of toolings : ± 10 to 30 minutes

- Changeover of recipes : ± 15 minutes

- Maintenance: Compact and simple design, yet reliable with a lifespan of minimum 20 years

The data is generic; actual values vary based on machine type, product recipe, usage patterns, monitoring, etc.

-

Can Serac support the full line of yogurt packaging?

Complete Packaging Turnkey Solutions

Serac can integrate seamlessly with your existing machines.

For new projects, we can also provide a full line of yogurt packaging with: blow-molder, unscrambler, conveyor, labeler, sleever, case packer, palletizer, etc.

Contact us with more details of your project and we’d gladly provide you with the answer.