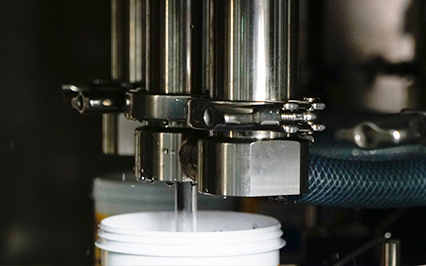

Versatile & evolutionary rotary filler-capper for all your liquid products!

Paints & Thinners Filling Machines

The major challenges faced by industrial coatings suppliers in today’s market include global competition, the high cost of energy, high increases in raw material costs and increasingly strict environmental regulations.

Paints, inks, coatings, lacquers, varnishes, wood, protection products, thinners, solvents.