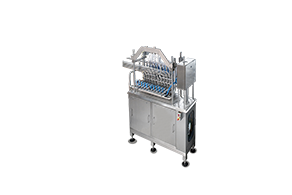

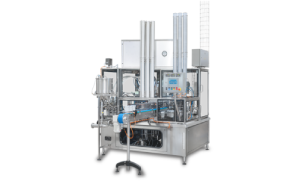

COMBOX (Blow-Fill-Cap) for Edible and Cooking Oils in PET Bottles

With PET bottles being the packaging of choice in the Edible Oil industry, Serac offers COMBOX, a one synchronised unit of PET Blower, Net Weight Filler, and Capper. Watch the video to see how Flexible, Cost-Efficient, and Reliable this solution is.

The PET Blower offers a low-to-medium work rate solution for edible oils with outputs of up to 18,000 bottles per hour. It can blow PET format with handles, too. The net weight filling technology ensures high filling accuracy. Serac has a unique filler solution dedicated to the edible oils. And the suction nozzles in particular, ensure clean filling with ZERO droplets.

With COMBOX you can have different bottle formats and oil types in one machine. The mold changeover only takes a few minutes, as well as the bottle filling changeover (Thanks to the unique bottle neck transfer). And the net weight product circuit allows quick change between oil types and avoids cross contamination. Apart from COMBOX, Serac provides a wide range of packaging solutions for all types of edible oils, including complete packaging lines.