Serac Bottling Machines for North American Sauce & Liquid Food Production

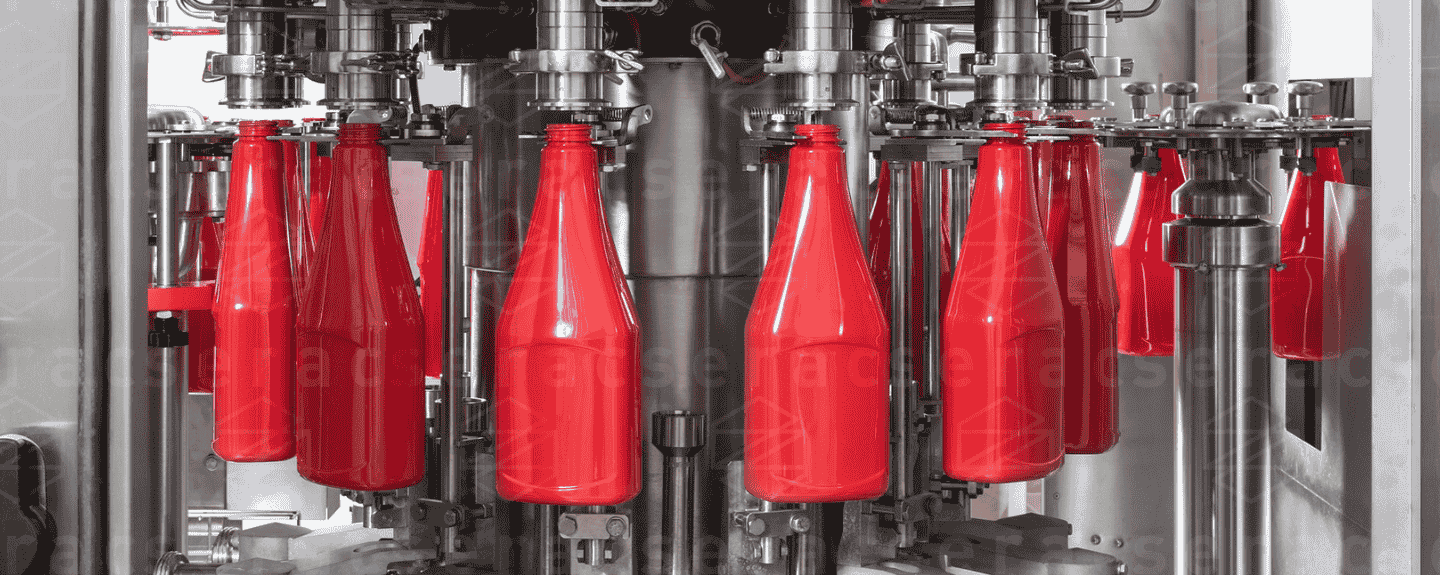

For over 40 years, Serac has specialized in net weight filling technology for sauces, condiments, and dressings. Our sauce filling machines handle everything from thin vinaigrettes to ketchups to viscous salsas, providing the flexibility and reliability food manufacturers need to meet growing demand while maintaining product quality and food safety standards.

With manufacturing and support in North America, Serac delivers filling lines that work with your existing infrastructure and meet U.S. and Canadian compliance requirements—including FDA, 3-A Sanitary Standards, and HACCP protocols.

Key Benefits of Serac Net Weight Filling Technology for Sauces & Liquid Food:

- ±1g accuracy per kilogram

- Unaffected by temperature changes

- Works with foamy or aerated products

- Minimal product waste between changeovers

- Thin to thick sauces

- Products with particles

- Optional overpressure for highly viscous products

- Handle 20:1 container range (e.g., 6.4 oz to 1 gal)

- Quick tooling changeover system

- Self-draining design with CIP integration

- Minimal product waste between runs

- 3-A Sanitary Standards compliant

- Hygienic nozzle (no contact with container)

- Cold fill capability for preservative-free recipes

- Decontamination treatments available

- Up to 40,000 bottles per hour

- Every container weighed during filling

- Real-time rejection of off-spec bottles

- Fewer moving parts

- No dynamic seals or diaphragms to replace

- Simple product circuit

Filling and Capping Machines for Sauce, Dressing and Other Liquid Food

Why Choose Net Weight Filling Technology for Sauces?

Serac’s net weight technology delivers consistent, accurate fills across varying viscosities to minimize the product giveaway that impacts profit margins. Our flexible sauce filling machines adapt to diverse container formats and recipes without complex hardware changes. Furthermore, the streamlined equipment design supports strict sanitary compliance while lowering total ownership costs.

| ✓ Superior Accuracy | 1g sigma per 1000g (0.1%), saves thousands of dollars monthly on high-volume lines |

| ✓ High Flexibility | Fills various shapes (bottles, jugs, with handles, jars), 7 Fluid Oz to 5 Gallons sizes and materials (PET, HDPE, LDPE, PP, PS Glass, metal) |

| ✓ Ideal for | Low-acid and High-acid products, hot fill and cold fill (Ketchup, BBQ Sauce, Mayonnaise, Mustard, Soy Sauce, Ranch Dressing, Balsamic Vinaigrette, Caesar Dressing, etc) |

| ✓ Meet food safety requirements | 3-A Sanitary Standards compliance, Clean-in-Place (CIP) and Clean-out-of-Place (COP) systems available, Full traceability with batch-level reporting |

Choose Net Weight technology when you:

- Fill multiple container formats and product recipes at medium-high speed

- Require less than 1% accuracy due to high giveaway sensitivity

- Run premium or high-value products like liquid dairy

- Need to ensure strict regulatory compliance and traceability

- Require high level of hygiene

Serac Net Weight Filling and Capping Machines’ Capabilities

For more details of Serac sauce bottling system capabilities, click on each section below:

Hygienic Design Standards

3-A Sanitary Standards Compliance:

- Food-grade construction: All product-contact surfaces use 316L stainless steel

- Cross-contamination control: Contactless self-draining nozzles with metal-to-metal closures; no threads, gaskets, pockets, or dead zones; fast-drain designs minimize holdover for safe, rapid changeovers.

- Full validation support: IQ/OQ/PQ documentation available for regulatory compliance

Advanced Clean-in-Place (CIP) Integration:

- Automated cleaning cycles reduce manual intervention

- Multi-directional cleaning inside filling tanks

- Closed-loop CIP system prevents exposure to cleaning chemicals

- Programmable protocols for different sauce viscosities

- Supports both CIP and SIP (Sterilize-in-Place) operations

Cleanroom-Ready Environment: Achieve ISO Class 5 purity with HEPA-filtered airflow and positive pressure cabins to prevent external contamination in sensitive packaging zones.

Decontamination Treatment Options: The sensitivity of your sauce recipes determines the level of hygiene and packaging treatments. Our sauce bottling machines offer multiple decontamination options:

| Treatments | Preform/ Bottles/ Jars | Caps (Closure) | Alu Foil |

| Filtered Air (Dry) | Yes | Yes | – |

| Pulsed Light (Dry) | – | Yes | Yes |

| Controlled H₂O₂ (Dry) | Yes | Yes | Yes |

Product Versatility & Applications

Product Range Capabilities:

- Ketchup, mustard, mayonnaise (standard & low-fat formulations)

- Hot sauce filling machine applications for sriracha, tabasco, buffalo sauce

- BBQ sauce bottling equipment for thick, chunky varieties

- Salsa filling machines for mild to extra hot with particulates

- Asian sauces: soy, teriyaki, sweet chili, hoisin

- Salad dressings: ranch, caesar, vinaigrettes, thousand island

- Pasta sauces: marinara, alfredo, pesto with herbs

- Specialty sauces: chimichurri, aioli, hollandaise

- Edible oils: Soybean oil, olive oil, canola oil, avocado oil, etc

Product Handling:

- Liquid to viscous (up to 40,000 cP)

- Foamy textures

- Particles up to 10×10×10mm – vegetables, herbs, seeds

Processing Solutions by Product Requirements:

Non-Sensitive Applications

Products: Hot filled sauces, vinegar-based, soy sauces, chili sauces

Processing: Hot fill up to 203°F (95°C) for shelf stability

Distribution: Shelf-stable, ambient storage

Equipment Type: Standard clean filling systems

Semi-Sensitive Applications

Products: Clean-label ketchups, regular mayonnaise, fresh sauces

Processing: Cold fill (ambient to 40°F) or controlled temperature

Distribution: Ambient or chilled storage

Equipment Type: Ultra-clean filling systems with HEPA filtration

Sensitive Applications

Products: Low-fat mayonnaise, preservative-free formulations, organic sauces

Processing: Aseptic cold fill with H₂O₂ decontamination

Distribution: Requires controlled environment, extended shelf life

Equipment Type: Aseptic filling systems with bottle & cap decontamination

Each system is optimized for specific product characteristics, ensuring food safety while maintaining quality and shelf life requirements.

Compatible Container Types

Container Materials:

- PET, rPET, HDPE, PP, PS, Glass, and Metal.

Serac also offers: PET Blower-Filler-Capper Multiblock

On-site PET bottle blow moulding delivers significant operational advantages:

- Complete design freedom—customize bottle size and shape to match your exact product requirements

- Reduced carbon footprint by eliminating empty bottle transportation

- Superior bottle quality at lower total cost of ownership

- Enhanced hygiene through seamless preform-to-fill integration, eliminating dust contamination risks inherent in pre-blown bottles

Container Formats:

Sizes: 1.7 fl oz to 2 gallons (50ml to 5L+)

Container range in one machine: 20:1 (e.g., 6.4 oz to 1 gal)

- Squeeze bottles

- Rigid PET bottles

- Glass bottles

- Wide-mouth designs

- Standard glass jars with twist-off lids

- Pails, Tight-Head Pails, JIB (Jug-In-Box), F-Style Jugs for bulk sizes

Container Handling Methods:

Neck Handling System: For bottles with consistent neck dimensions – faster changeover, reduced contamination risk

Bottom Handling System: For diverse shapes, jars, and containers without necks – maximum flexibility

Sealing & Closure Options

Induction Heat Sealing:

- Controlled temperature, pressure, and time parameters

- Foil-in-cap integration for tamper evidence

- Roll-fed aluminum foil application system

- Suitable for PET, HDPE, PP containers

Closure Types:

- Screw caps (standard threading)

- Twist-off (easy consumer opening)

- Crown caps (beverage applications)

- Snap-on (rigid container closures)

- Custom and specialty formats

Electronic Capping Technology

- Torque-controlled application with real-time monitoring

- Handles flat caps, flip-tops, disc caps, trigger sprays

- Orientation capability for branded caps

- Pump & Dispenser Applications: hand pumps, trigger sprays, etc.

- Controlled insertion depth prevents damage

- Rapid format changeover

Traceability

Our sauce filling machines deliver complete production visibility and control.

- Complete Records: Track every container with full batch data, fill weights, timestamps, and operator information for regulatory compliance.

- Quality Monitoring: Real-time performance tracking with automatic defect rejection and instant alerts for out-of-specification products.

- System Integration: Connect to MES/ERP systems with remote monitoring, cloud analytics, and predictive maintenance capabilities.

Product Videos

North American Liquid Packaging Machinery Manufacturer

Serac Inc designs, engineers and builds machines in the USA. Our proximity is enhanced by our international presence & expertise, allowing us to offer unmatched services at the highest standards across the Americas.

Welcome to Serac Inc, where we make filling, capping and sealing machines for sauce and liquid food products in rigid packaging

Our factory in Carol Stream, IL is open for Visits.

📍 View Serac Inc on Google Maps

To book a factory visit: [email protected]

To inquire about our solutions: Fill in our contact form here.

Support from After-Sales: Visit this page.

Your Questions, Answered (FAQ)

How does filling accuracy (product giveaway) impact my profitability?

Overfilling to stay compliant means “giveaway” and it can cost tens of thousands. Net Weight filling is the solution to reduce this cost.

Sample Case: The Cost of Product Giveaway

*Using assumptions of production & cost

Product & Cost: Clean-Label Sauce @ $2.00 per kg

Annual Operation: 300 days/year (6 days/week × 50 weeks)

Daily Production (before calculating Downtime):

- 12 oz Clean-Label Sauce (8 hours @ 15,000/hr) = 120,000 containers

Total Annual Production: 36.0 Million containers

Target weight: 340 grams per container

Based on this production volume, the only variable is the filler’s accuracy:

|

|

A note on accuracy: Net Weight fillers achieve 0.10% accuracy (e.g., ±0.34g per 340g target) compared to standard fillers with fixed ±2g variation. For a 12 oz sauce bottle, this represents sigma of 0.10% versus 0.59% — a significant improvement that directly reduces product giveaway costs.

This is an illustrative example. Actual savings vary based on your specific operation parameters.

How much does a sauce filling machine cost?

The cost of a sauce filling machine depends on your specific project. The main factors include:

- the packaging format (shapes, materials, sizes),

- your product recipes (viscosity, density, foaming),

- required production speed per minute or hour.

Please contact us with these details (click here) and our US-based team will provide a detailed estimation.

What are the downtimes with your sauce filling and capping machines?

Our machines are designed for high hygiene and flexibility to minimize downtime. Typical non-production times are:

- CIP (Clean-in-Place): ± 60 to 180 minutes

- Tooling Changeover: ± 10 to 30 minutes

- Recipe Changeover: ± 15 minutes

Note: The data is generic; actual values vary based on machine type, product recipe, usage patterns and local regulations.

What is the typical lifespan of your filling machines?

Serac machines are designed for reliability and longevity. With proper preventative maintenance (which our HMI can help you schedule), our machines have a typical lifespan of 20 years or more in a demanding dairy production environment.

Can Serac support the full line of sauce packaging?

Yes. Our sauce filling machines can integrate seamlessly with your existing equipment.

For new projects, we can also provide a full turnkey packaging line, including blow-molders, unscramblers, conveyors, labelers, sleevers, case packers, palletizers, and more.

Do you provide service and support in Canada?

Yes. While our primary factory is in the USA, our North American service team provides full support for our Canadian customers. This includes dedicated installation, commissioning, maintenance, and technical support.