“ Servo motors are essential mecatronic components for the automation of complex movements and frequent format changeover. They make your filling lines smarter. “

With brushless servo motors, drive systems can be simplified and are thus more reliable as well as easier to maintain. On feeding screws for example, it is possible to remove gear wheels, gimbals, angular gearboxes, etc. and to significantly reduce the backlash.

Servo motors enable to better synchronize the container infeed with the pace variations of the filling station. It is for example possible to use servo motors in association with an encoder to stagger containers when necessary. A good synchronization is essential, especially at high speed, to avoid container jams and falls. An issue which tends to become more common with the development of complex, unstable shapes for flasks and bottles.

Optimum synchronization will protect containers and reduce downtime. And if all the mechanical synchronization functions are replaced mecatronic systems, it is even possible to get rid of accumulation areas to save some floor space.

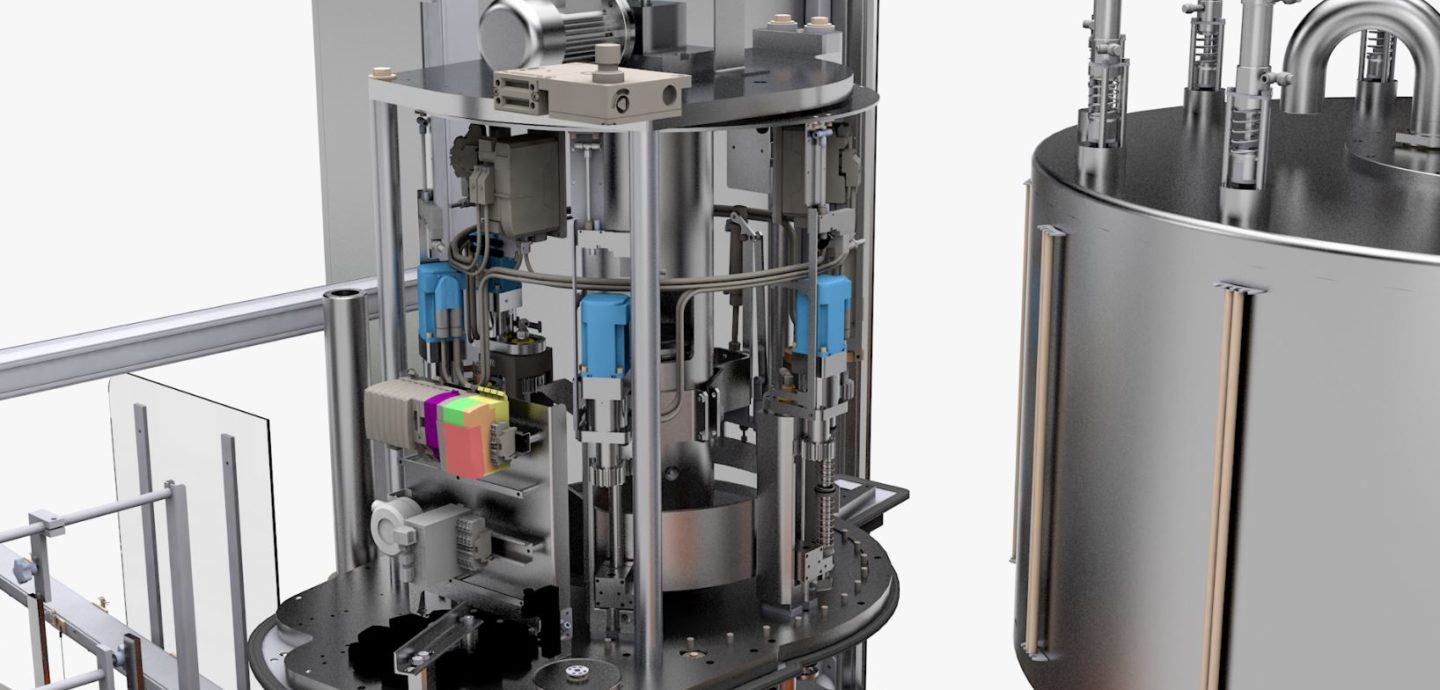

Servo motors make it possible to define and control complex movements with a high level of accuracy and dynamics. A benefit which leads to an optimization of cycle times and thus to a better productivity. Through the association of servo motors with electric actuators on dosing nozzles it is for example possible to modify positions and speeds during the filling cycle in order to adjust the flow to the parameters of each product/container pairing, as well as to variations in air content, temperature or viscosity. Another example with the screwing turrets : servo motors reduce changeover time and can halve the duration of the up and down cycle through controlled acceleration curves and smooth motion.

Servo motors make it easy to manage numerous cam profiles, without any manual action yet with perfect control on motion parameters. This enhances the flexibility and versatility now required for machines due to the fragmentation of many markets.

With servo motors, it is for example possible to use the same machine for oriented push-on caps, oriented screwed caps with torque and/or position control, or to insert pump dispensers and caps on the same turret. The capping profile can be adjusted to each bottle/cap pairing as well as to variations in hardness coming from different colors.

Servo motors also provide solutions to respond to new requirements for quality assurance documentation and traceability. On a capping turret for example, they ensure a higher torque reproducibility and offer the possibility to record the results for every bottle. Available in production reports, these data allow to assure that each container has been properly sealed, with documented evidence.