Optimizing Dairy Production with Advanced Dairy Cups Filling Machines

Serac’s Dairy Cups Filling Machines present a versatile solution for any dairy products, including yogurts, cream cheese, and more, catering to preformed cups of various sizes. These cup fillers are ideal for products such as yogurts, cream cheese, sour cream, cottage cheese, desserts, baby food, and milk drinks in cups, demonstrating their ability to handle a wide range of filling tasks with precision. To explore more about how Serac is addressing the needs of the dairy industry with innovative packaging solutions, visit our dairy products packaging solutions page.

The rotary and linear Fill-Seal Dairy Cups Filling Machines by Serac are designed to efficiently manage outputs from 2,000 to 40,000 cups per hour, thus answering the needs of both established and new players in all market segments. Alongside the bottle filling machine options proposed by Serac, they offer a full array of options to meet customer expectations such as on-the-go consumption and extended shelf-life, indulgence, or natural market segments.

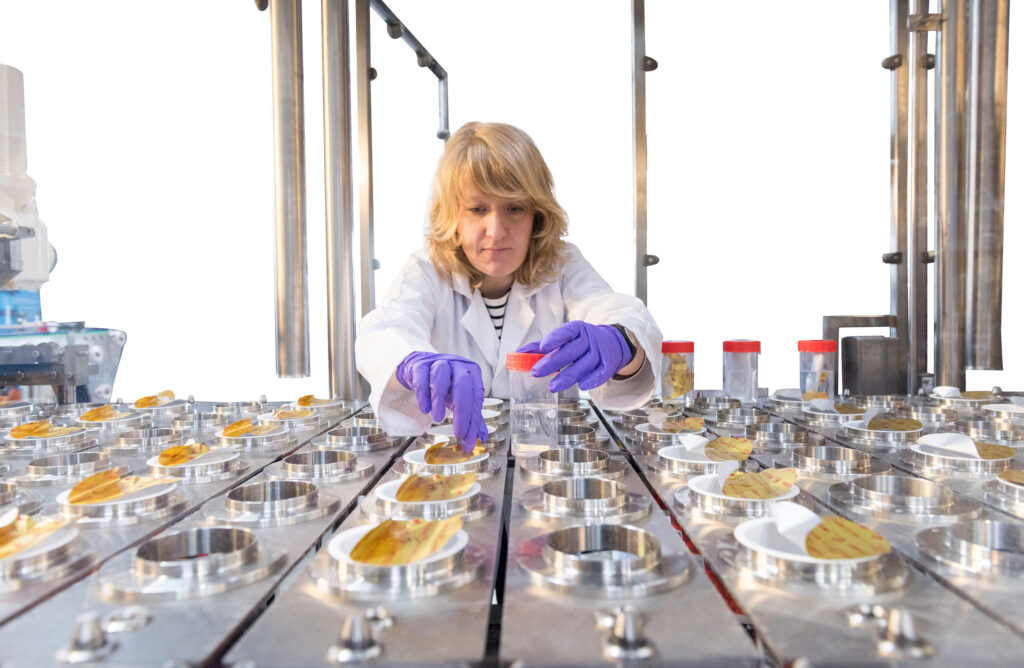

As an innovation partner, Serac works hand-in-hand with dairy manufacturers and anticipates their needs for preservative-free products or high-end yogurt recipes by developing cutting-edge decontamination, cleaning, and automatic cup filling machine solutions.

For instance, Serac’s innovation extends to the Dairy Cups Filling Machines with a patented decontamination system that ensures efficiency by continuously monitoring H2O2 concentration as well as homogeneity treatments, and automatically stopping the machine when parameters are outside tolerance limits.

Using pulsed light technology for many years on caps and foils, Serac has also extended it to cups, both on linear and rotary machines. Pulsed light combines the sterilizing effect of UV rays with the impact of high-power flash to destroy microorganisms, enabling a 3-log reduction with a single flash, and thus opens “UV-light-based” decontamination solutions to more sensitive products.

UV and pulsed light decontamination are dry and chemical-free, but pulsed light is a sustainable and low energy-consuming alternative to H2O2 and UV for ultra-clean packaging. Mainly used in Europe and the USA, pulsed light cup decontamination is also setting foot in other areas, showing the growing interest in this technology.

Committed to Supplying Highly Reliable and Flexible Cup-Filling Lines

Indexed rotary cup filler and linear Fill-Seal machines are designed with all Serac’s expertise in hygienic design, offering several configurations for clean or ultra-clean packaging. Particular attention is also paid to lid heat-sealing to ensure both food safety and easy opening.

These machines are appreciated for their dosing accuracy and mechanical reliability, that avoid product losses and reduce both production downtimes and maintenance costs. They are capable of dosing liquid and high-viscous products with an efficient volumetric dosing and offer fast changeovers, showcasing their versatility as cup fillers.

Flexibility, a cornerstone of Serac’s philosophy, is embodied in our Dairy Cups Filling Machines, which are designed to adapt to fast production shifts and recipe changes, ensuring a seamless transition for dairy manufacturers. This is further enhanced with the Modulo nozzles, a revolutionary concept that consists of a fixed part and several heads that are changed very easily according to the product’s viscosity without requiring disassemble of the full nozzle when switching from one product to another.

Finally, aiming at being unique, newly developed products call for a packaging machine that is modular and adjustable rather than highly standardized. This is why Serac is committed to providing dairy manufacturers with scalable and flexible solutions, plus close technical support throughout their projects.

For more information about our machines and our know-how, please contact us.