Ideal for the filling of processed dairy desserts

Expert dosing systems to integrate in "Fill/Seal" and "Form/Fill/Seal" machines

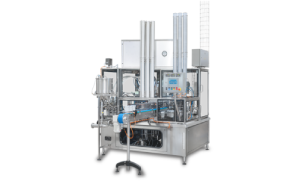

Filling station

- High performance

- Easy to integrate in existing lines

- Accurate and versatile dosing

Containers: pre-formed cups, form-fill-seal cups, trays, pouches

Materials: PET, PP, PS, Aluminum, Glass, Carton,…

Outputs: up to 24 filling heads