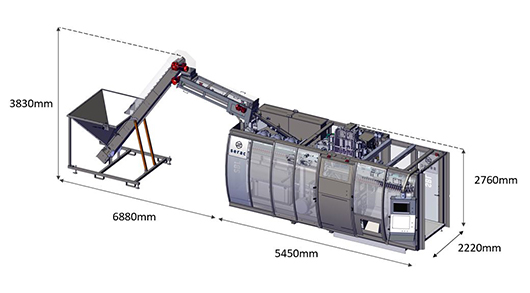

Ideally suited for high value added products and low/medium size batches

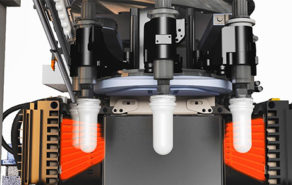

PET bottle production at small and medium outputs

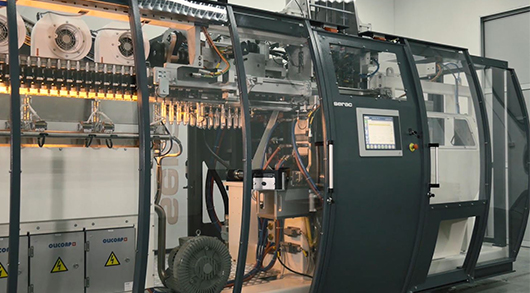

Bottle manufacturing

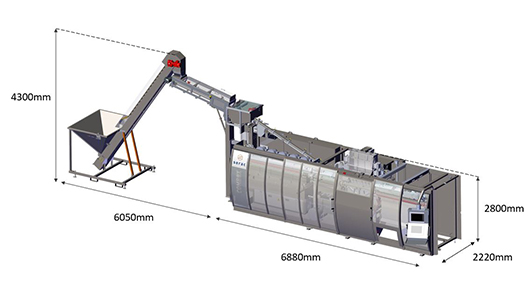

- Total visibility and easy access for the operator

- Optimised change of format

- Power saving

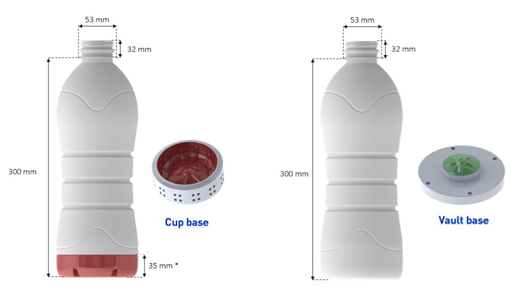

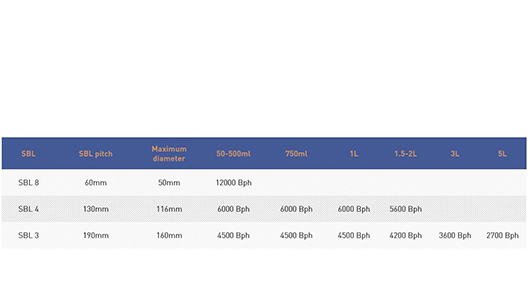

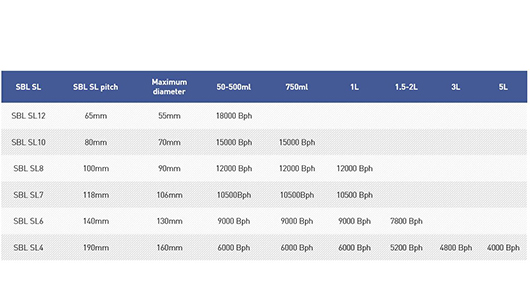

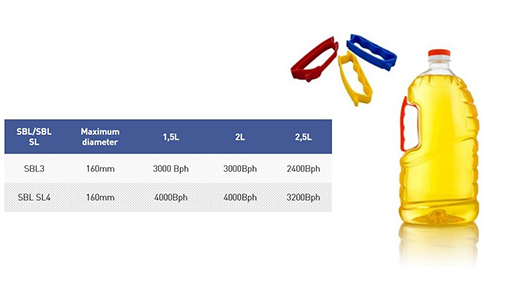

Containers: 50 ml to 5 l

Outputs: Up to 18,000 containers per hour (500 ml)