Overall engineering, from bottle blow-moulding to shrinkwrapping

Serac has led the development of the entire line (comprising of a stretch blow-moulder, an aseptic filler/capper, label and shrink sleeve applicators plus secondary and tertiary packaging units).

Project included equipment selection, integration follow-up, factory acceptance tests and site acceptance tests, for which Serac acted as the single responsible contact person of FUN.

Serac’s assignment was no real surprise as the company is the worldwide leader of low-acid products aseptic bottling, with 44 years of experience and over 78 lines running. FUN and SPX FLOW were thus assured that each step of the packaging process would be carefully assessed to ensure premium quality and food safety.

“ Deliver cutting-edge solutions in terms of hygiene, efficiency and packaging innovation to support Food Union’s (FUN) vision of innovation in China. “

Rasa dairy drinks packaged with a Serac Aseptic System 5

Premium quality and attractive packaging to change the landscape of Dairy products in China

Aseptic bottling is the final stage of a whole process dedicated to taste, nutritional value and food safety, which relies on breakthrough technologies to produce premium quality products. Designed to entice Chinese consumers and meet their convenience requirements, FUN products were to be presented in an appealling, reclosable packaging. Choice went naturally to white PET bottles which are increasingly used on Chinese premium market segments.

As a full partner on primary packaging, Serac also brought its support at the bottle specification stage.

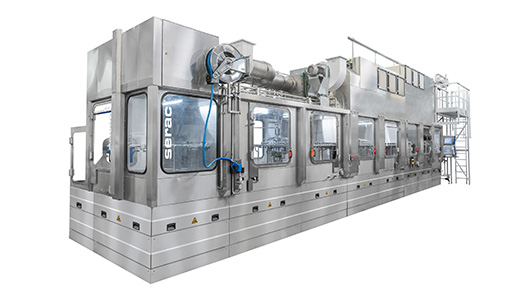

Serac aseptic filler installed at Food Union – SAS 5

Highly secured process

The line has been validated according to European protocols for aseptic machines. The filling and capping unit benefits from state-of-the-art aseptic technology and to ensure no particles enter the sterile zone, only a minimum amount of equipment remains present in the sterile zone.

Particular attention has been paid on H2O2 vapour bottle decontamination, which is highly secured and fully traceable. The process is defined and validated for each bottle format through challenge tests, and continuously monitored during production through Serac’s patented probe.