“ In Japan more than elsewhere, production space is a scarce resource. It was thus important that the proposed solution can do all it is intended for in a minimum of space. “

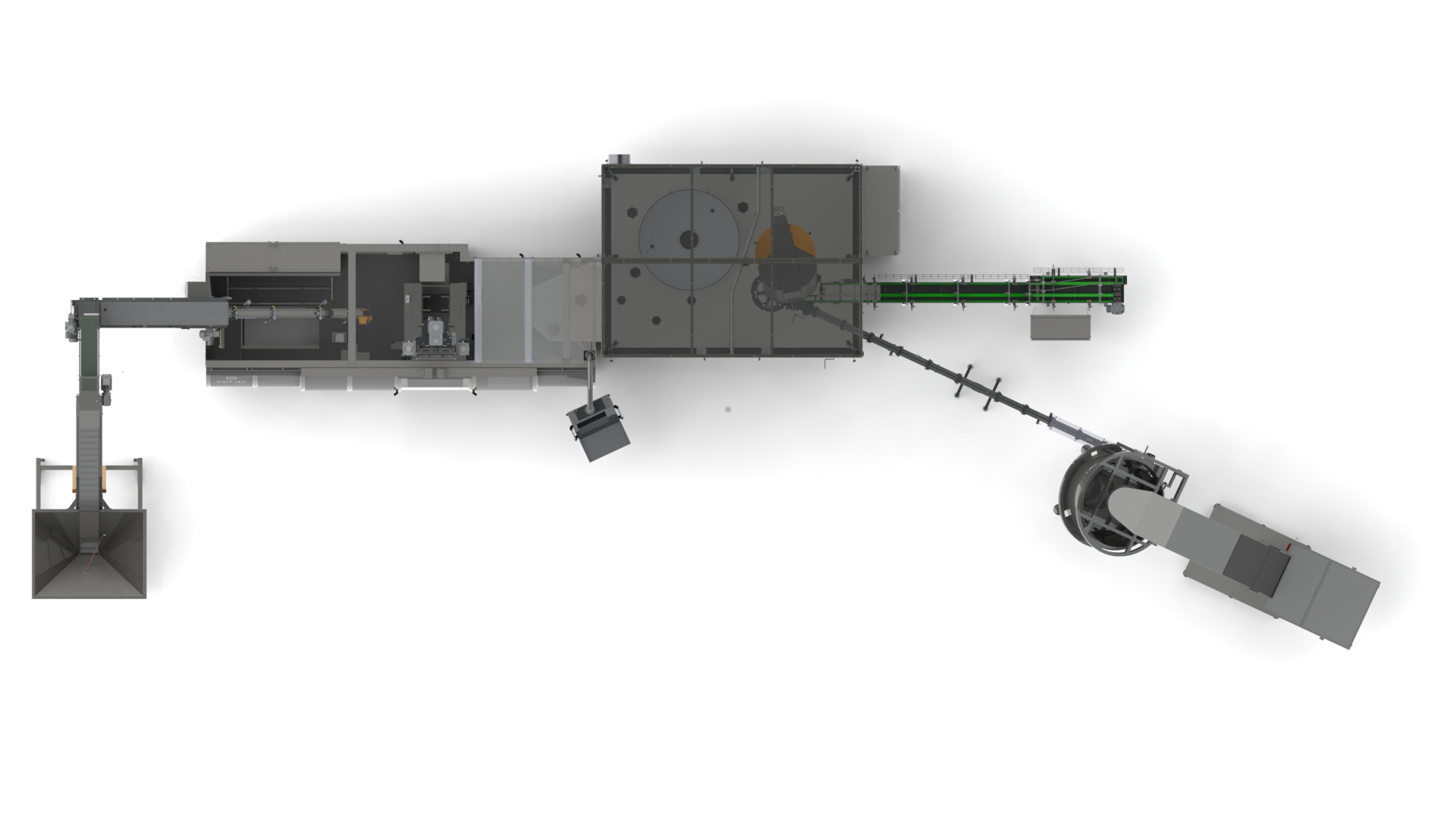

Footprint reduction of 25% and synchronized functions

Japanese consumers are entitled to be highly demanding with regard to the products they buy, urging manufacturers to rival on creativity to stand out from their competitors. One of them, specializing in personal care, has recently invested in a blow-fill-cap multifunction block from Serac. A choice guided by the will of answering the needs of a highly segmented market with trendy packagings, while keeping costs under control.

Combox block : a production tool to anticipate the future

The Combox block sold in Japan is currently producing 1 liter square pump bottles and 500 ml oval bottles with screwed caps, all made of white PET. This versatility was a salient choice criterion for the manufacturer, who wanted to anticipate the future by choosing an equipment that offers the possibility to develop new products with total creative freedom.

Serac’s Combox block indeed distinguishes itself by the extreme diversity of applications it can cover:

The PET stretch blow moulding unit can produce all types of containers (square, round, oval, with flat shoulders or wide flat base), in clear or coloured PET, with a capacity ranging from 50 ml to 1 liter and even more if necessary. The weight filler is also highly scalable. Various options can be added to fill viscous products such as soaps and creams, but also oils in addition to liquids. Finally, the capping unit is designed to deal with push on as well as screwed caps with, for the latter ones, the possibility to control torque effort and orientation.

Maximum flexibility in minimum space

In Japan more than elsewhere, production space is a scarce resource. It was thus important that the proposed solution can do all it is intended for in a minimum of space.

With regard to this requirement, the Combox block comes with the benefit of having neither conveyor nor accumulation area, due to the output synchronization of the three units and a positive transfer all along the packaging process. As a consequence, the Combox block’s footprint is 25% smaller compared to a conventional line.

Reduced production costs and uncompromising quality

The Combox block allows to generate significant savings on production costs without compromising on quality – quite the contrary. Again a salient equipment choice criterion on the Japanese market. On-site stretch blow moulding allows to save on raw material, transportation and storage, while avoiding to discard bottles scratched and distorted during handling. Positive transfer from blowing to capping also contributes to protect containers from any damage.

The Combox block allows to generate significant savings on production costs without compromising on quality – quite the contrary. Again a salient equipment choice criterion on the Japanese market.

On-site stretch blow moulding allows to save on raw material, transportation and storage, while avoiding to discard bottles scratched and distorted during handling. Positive transfer from blowing to capping also contributes to protect containers from any damage.

In-lign bottle manufacturing brings up to 15% increase in productivity compared with other solutions as it avoid to tare containers.

Serac’s weight filling technology benefits from an « Automatic Weighing Instrument » (AWI) type approval ; it thus allows to reduce drastically sampling and control procedures, as well as to avoid to overfill containers to make sure to conform with the nominal quantity printed on the packaging. The Combox block also benefits from Serac’s fast tool changeover systems and CIP solutions, which are optimized to reduce downtime. It can thus reach an output of 18 000 bottles / hour on a 500 ml capacity, with an efficiency rate over 98%.

Finally, the Combox block can be operated by a single person, which also generates savings on labour costs.

All manufacturers of liquid personal care products can make use of the benefits of the Combox block to develop their market shares on highly segmented and competitive markets, by playing with PET properties to stand out in the shelves. They can become trendsetters in packaging with new shapes or new dosing concepts, and offer wider ranges at lower costs using PET transparency.