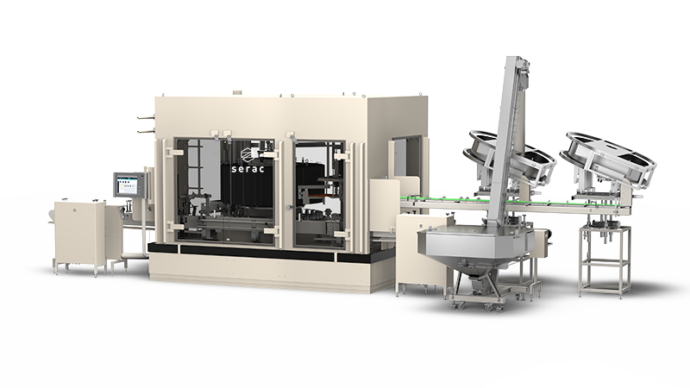

The all-in-one solution for all your liquid products, container sizes and shapes!

The long-term solution for corrosive products

Filling & Capping

- Design unaffected by corrosion

- Hermetic enclosure

- Pressurisation of electrical elements and mechanical drives

Materials used: polyethylene, polypropylene, titanium, hastelloy, stainless steel 316L

Outputs : up to 36,000 containers per hour (1l)