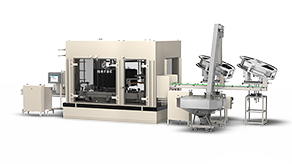

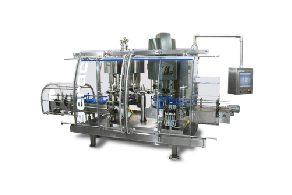

Versatile & evolutionary rotary filler-capper for all your liquid products!

The all-in-one solution for all your liquid products, container sizes and shapes!

Filling

- Clean filling

- Long life

- Excellent cleanability

Containers: from 100g to 60kg, 700 mm maximum height

Materials: PET, PP, PS, Aluminum, Glass, …

Outputs: up to 700 containers per hour (1l)