Corrosion proof materials used by Serac in its RC filling machines include polyethylene or polypropylene, 316L stainless steel, titanium and even Hastelloy.

When having to invest in a new filling machine, manufacturers of chemical products such as bleach or descaling agents are confronted with a particular issue: machine lifetime. On one hand corrosion can drastically reduce the operational life of standard machines, on the other, the acquisition cost of corrosion-proof equipment is significantly higher. Manufacturers thus must decide between short-term and long-term investment, the final choice depending mostly on profitability and market adaptation criteria.

Acquisition cost must be balanced with TCO and OEE.

Aggressive products can significantly reduce machine’s lifetime if they are not designed to be corrosion-proof. Spilled liquids can seep in the machine body and spread corrosion across components, thus generating high maintenance costs and machine downtime. When properly designed and built to withstand contact with corrosive products, a filling machine can generate yearly maintenance costs that represent less than 1% of the acquisition cost. With less breakdowns and maintenance operations, the overall availability of the machine is obviously higher, and production can be conducted without trouble over a longer period.

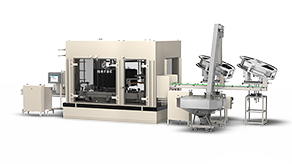

As we can see, from ROI point of view, several arguments plead in favor of machines specifically designed to withstand corrosion over a long operational lifetime. However, to win the final decision, such machines still must be flexible enough to make sure they will be able to adapt to market evolutions over the long term. With undisputed experience gained through its long-term collaboration with HPC industry leaders, and mastery over all kinds of packaging’s (angle or straight necks, complex caps…) and formulas (concentrated, scented…).

Serac positions itself as a reliable partner for developing machines with a long-term business overview. When designing its RC filling machine range, Serac has also emphasized flexibility by using the Plug-On® technology for format changes. Plug-on change tools enable the production of multiple formats on the same machine, with quick dismantling and assembling. Combining profitability with market adaptation, Serac’s RC filling machines offer all the benefits required for investing in long-lasting production equipment.

“ A design unaffected by corrosion does not limit its use to chemical resistant materials. One must identify the highest level of resistance for all components using materials, coatings and specific protection measures. Limiting the number of weld seams also helps extend the working life. “

Filling machines play a crucial role in the packaging industry, particularly when it comes to handling chemical liquids. However, this task is not without its challenges. The unique properties of chemical substances present specific hurdles that must be addressed to ensure both safety and product integrity.

How to handle hazardous substances?

One of the primary challenges in filling chemical liquids is the handling of hazardous substances. Many chemical liquids possess properties that make them potentially harmful to human health and the environment. These substances may be corrosive, toxic, reactive, or flammable, requiring careful handling throughout the filling process. Specialized equipment and protocols are necessary to mitigate the risks associated with these substances.

The safety of operators is paramount when dealing with chemical liquids. Exposure to hazardous chemicals can result in severe health consequences, including chemical burns, respiratory issues, and systemic toxicity. Proper training, personal protective equipment (PPE), and engineering controls are essential for safeguarding the well-being of personnel involved in the filling operations. Additionally, adherence to regulatory standards and guidelines is crucial to minimize the risk of accidents and ensure compliance with safety regulations.

Proactive protection choose Serac for operator safety:

Serac machines specifically designed for chemicals products include a whole array of add-ons to ensure that operators are not exposed to harmful substances.

Proactive protection of the equipment is essential as well since it avoids repeated contact with harmful products where not intended. Proactive protection is obtained through a clean production environment (less drips, for example), full mastery of corrosive fumes, operational reliability and high cleanability.

For flammable products, Serac ATEX/XP machines are specifically built for safe operation. For example, the stainless-steel cabin includes a roof and reinforced glass doors. All electric and electronics are protected with over pressure IIBT4 electrical parts are protected with sleeves. All machines’ parts are connected to earth, electrical and pneumatic cables are enclosed in stainless steel trucking, etc.

For products with bleach, Serac’s RC filling machine range offers a totally closed and tight cabinet equipped with proven extraction mechanisms to avoid the propagation of vapors, and an automatic cut-off system connected with doors opening.

Managing Chemical Compatibility:

Chemical compatibility is a critical consideration in the selection of materials for filling equipment and packaging. Certain chemicals may react with specific materials, leading to corrosion, degradation, or leakage. Compatibility testing must be conducted to ensure that the chosen materials are suitable for the intended applications and do not compromise product safety or quality.

Design not only needs to be chemical resistant materials for sensitive parts. Higher robustness must be sought after for all components, through specific materials, coatings, and protection methods (such as overpressure for electrical parts and mechanical drives). Minimizing the number of welds in the machine design also contributes to extend its lifetime.

When it comes to filling bleach, corrosion needs to be taken very seriously to avoid maintenance costs and machine downtime.

Since various corrosion-proof materials can be used in the building of the filling machine, and no single combination proves ideal for every product, design should always be carried out in close partnership with the end-user. With his own parameters in mind, he will be able to guide the machine manufacturer towards the proper choice of materials for the environment considered and thus benefit from the longest possible lifetime for his machine.

Serac uses diverse material to Ensure machine longevity:

Corrosion proof materials used by Serac in its RC filling machines include polyethylene or polypropylene, 316L stainless steel, titanium and even Hastelloy.

Serac also proposes Halar coated stainless steel tanks that offer higher resistance to mechanical stresses, chemicals and temperature. Such tanks are particularly suited for highly viscous products that require overpressure and applications dealing with hot fluids or hot cleaning agents.

Serac regulatory compliance to Ensure safety :

Compliance with regulatory requirements is essential in the filling of chemical liquids. Regulatory agencies impose stringent standards to protect human health, safety, and the environment. Filling equipment must meet regulatory specifications for safety, accuracy, and reliability. Additionally, proper labeling and documentation are necessary to ensure product traceability and facilitate regulatory inspections.

For potentially explosive atmospheres, Serac provides Special finish ATEX/XP Equipment:

Serac has been working with the top leaders in the agrochemical’s fields, ensuring the needs of the most demanding companies.

Would you like to talk to our teams about a filling project? Contact-us