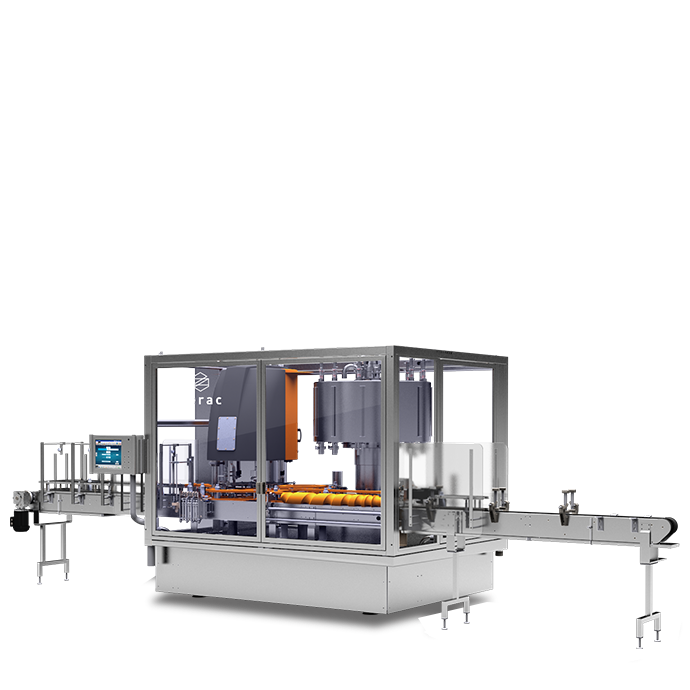

Hygienic filler for cosmetics with brushless capping with traceability of the actual torque.

Containers: from 100g to 60kg

Materials: PET, PP, PS, Aluminium, Glass, …

Outputs: up to 42 000 containers/h (1 L)

Electronic weigh filler-capper, made of 304 stainless steel and designed to fill a wide variety of products into various containers sizes and shapes. Our rotary weigh filers are the ideal solution to fill any homogeneous liquid products, including food, fragile, abrasive, corrosive or inflammable products.

As a standard, the machines are built completely in stainless steel (or adapted materials such as titanium or hastelloy)

Our machines are built to last and integrate proven, long-lasting technology and materials with low maintenance. The solid structure reduces vibrations, increases accuracy and provides a safe production environment for your operators.

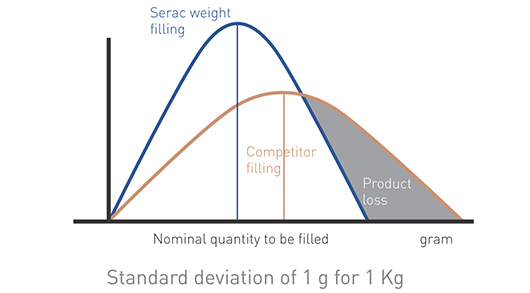

Weight filling is the only filling technology that controls the amount of product as it fills the bottle, not after!

The net weight fillers of Serac can be expected to save considerable amount of product for the manufacturer through reduced product giveaway on account of high fill accuracy. An accuracy of approx. 1g/liter (1 sigma standard deviation) can be expected! The savings often completely offset the price of the machine in a few years of operation.

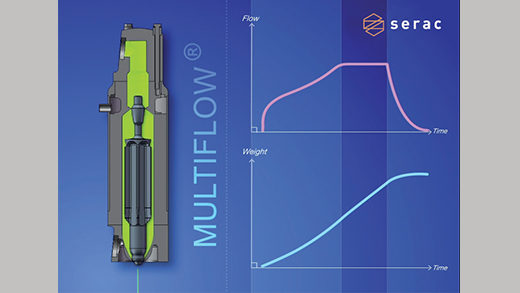

Multiflow nozzles and FCS+ HMI are the ideal combination for clean filling of foamy products.

With the new version of nozzle, there is no need to compromise between foamy and viscous products on the same filling line. The operator simply selects the product & package from the machine interface to adjust the filling cycles. There is no calibration required, no settings to alter and downtime is considerably reduced.

Plug-on: Ultra-rapid container circulation tool change system.

Serac uses the Single Minute Exchange of Die –SMED- methodology to optimize both the accuracy of machine settings and the change-over speed.

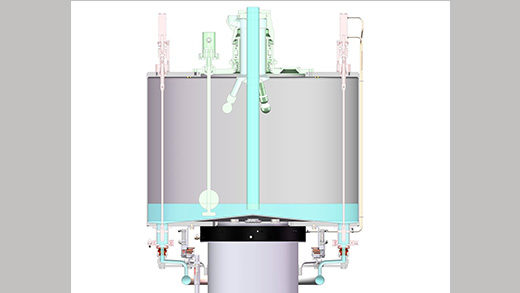

Serac solutions are adapted to stringent regulations for the treatment of effluents.

Our CIP system is designed to remove all product traces with minimal use of cleaning solution, both inside and outside of the tank (scales, table, filling nozzles). We also provide closed loop “dry” cleaning with automatic placement of collectors under the filling nozzles.

We design and assemble our own capping turrets to fit your needs and fully control the maintenance

Hygienic filler for cosmetics with brushless capping with traceability of the actual torque.

Filler capper for detergents with closed loop “dry” CIP system.

Filler capper for edible oil with fully enclosed cabin

Filler capper for automotive products with camera detection of container orientation.

Fully enclosed clean filler capper for sauces with internal bottle treatment.

The all-in-one solution for all your liquid products, container sizes and shapes!

Ideally suited for high value added products and low/medium size batches

Pioneer in weight filling for liquid food on rotary machines since 1969 (glass, metal, rigid plastic), Serac is a leading ...

We have been designing and manufacturing packaging machines for home care products for over 40 years. This extensive experience is ...

Your customers expect the best out of your products, and it is for this reason that we strive to maintain ...

Whether you need a complete packaging line for standard high-volume lubricants or for small batches of different automotive products, our ...

The major challenges faced by industrial coatings suppliers in today’s market include global competition, the high cost of energy, high ...

For such high value products which tend to be more and more concentrated in small formats, dosing accuracy is critical. ...